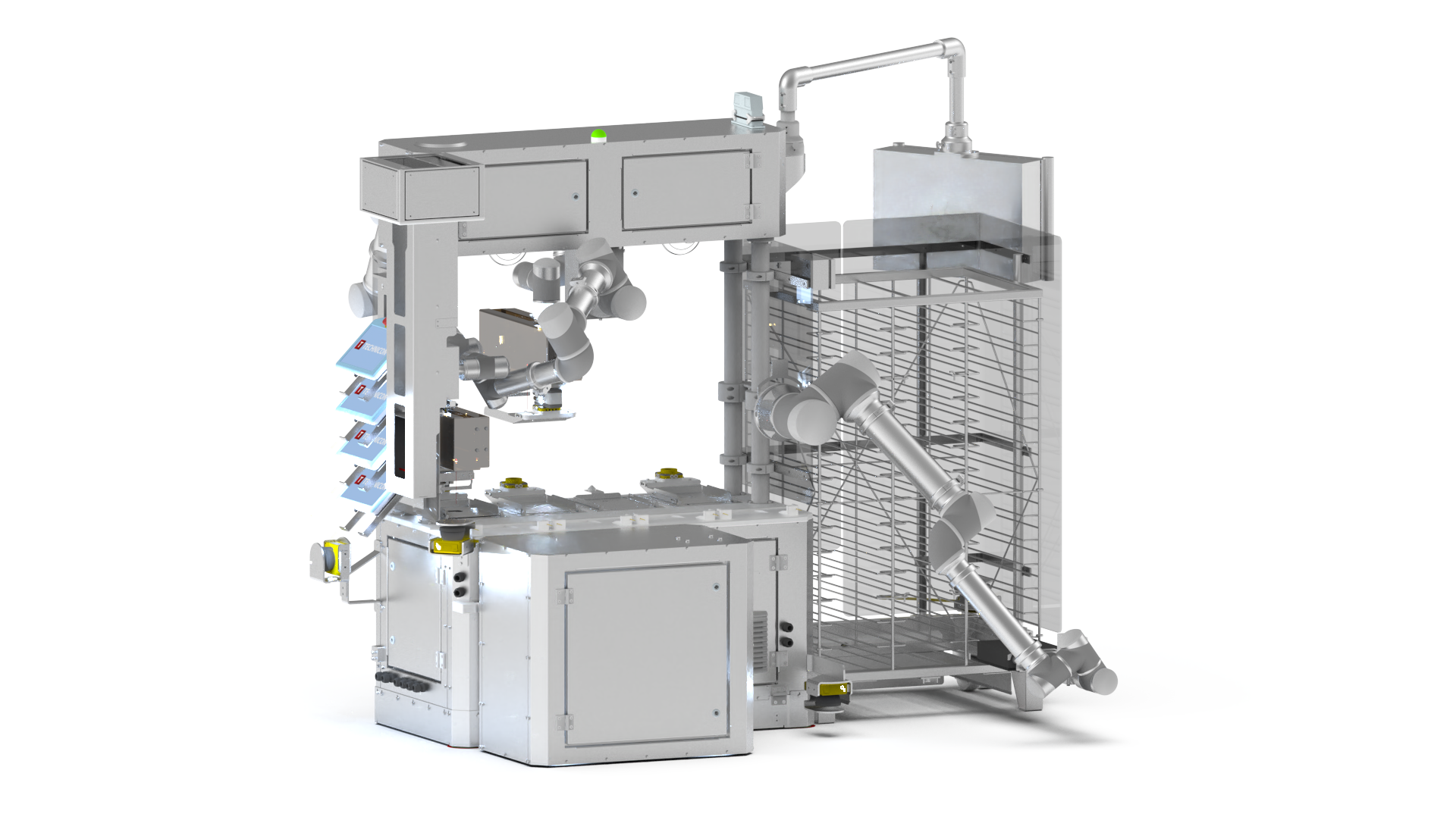

PACKAGING

Automatic Cartridge Outfeed

Automatic Cartridge Outfeed strengthens the scope of better jobs, improves EHS, improves productivity, secures product quality and frees up operators' time.

Up till now the repetitive process of handling the cartridges from the filling line to box and into racks has been done manually. This is normally a field that requires trained operators with experience and skills to do the handling of the cartridges without risking causing chips and crack or crushers.