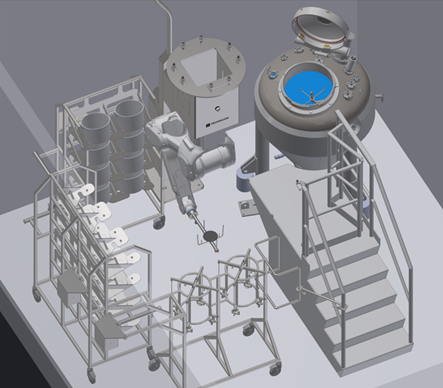

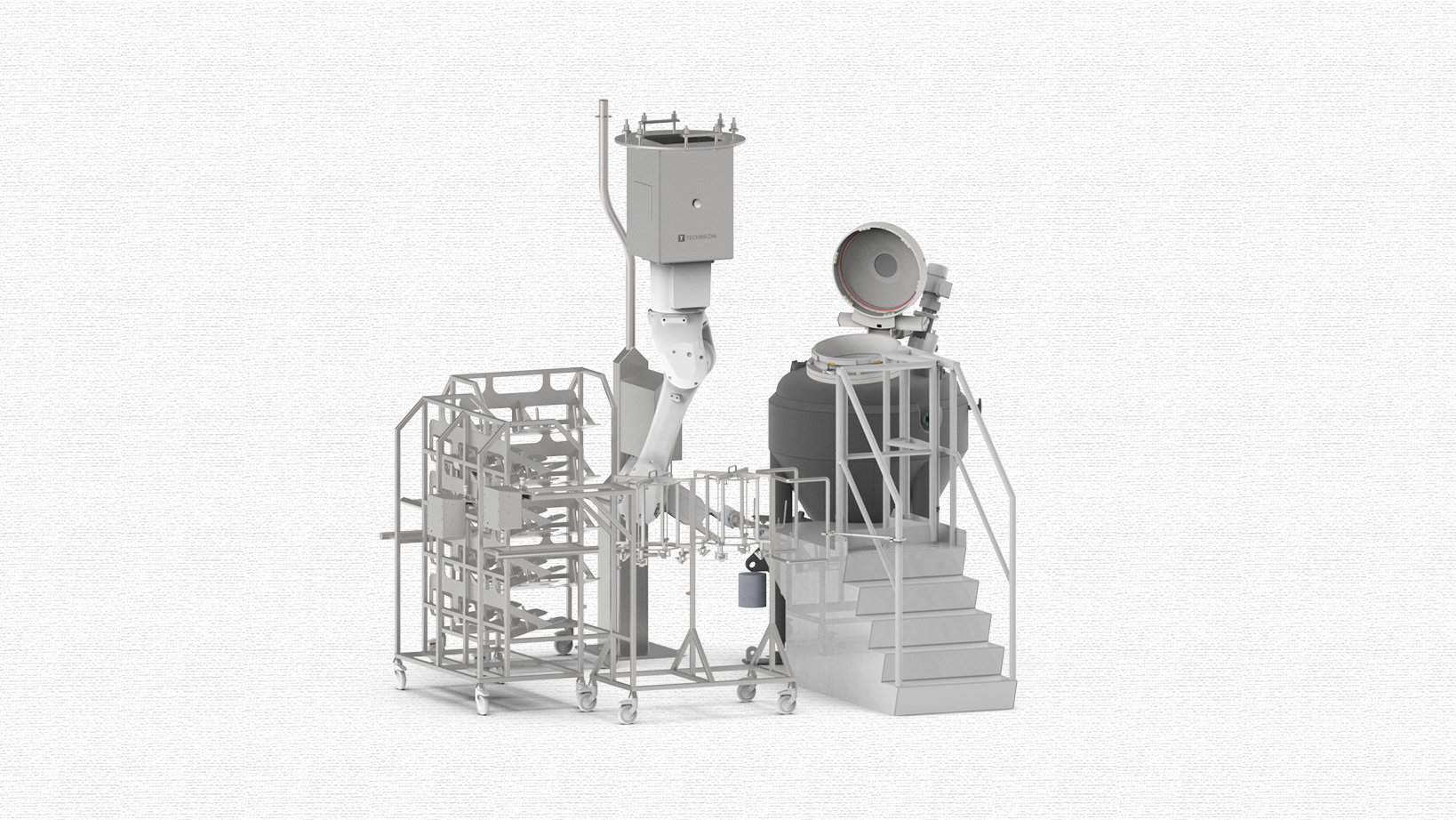

API

Bucket Handling

Scalable API automation solution for clean rooms. A stable robot with customized vacuum tool reliably, gently, and efficiently unpacks and empties filled 10L buckets.

Manual emptying of filled buckets in clean rooms can be highly labor-intensive, costly, and poses an increased risk of human error and contamination. The effort to minimize such cost and risk and stay ahead of compliance is essential.