Fill & Finish

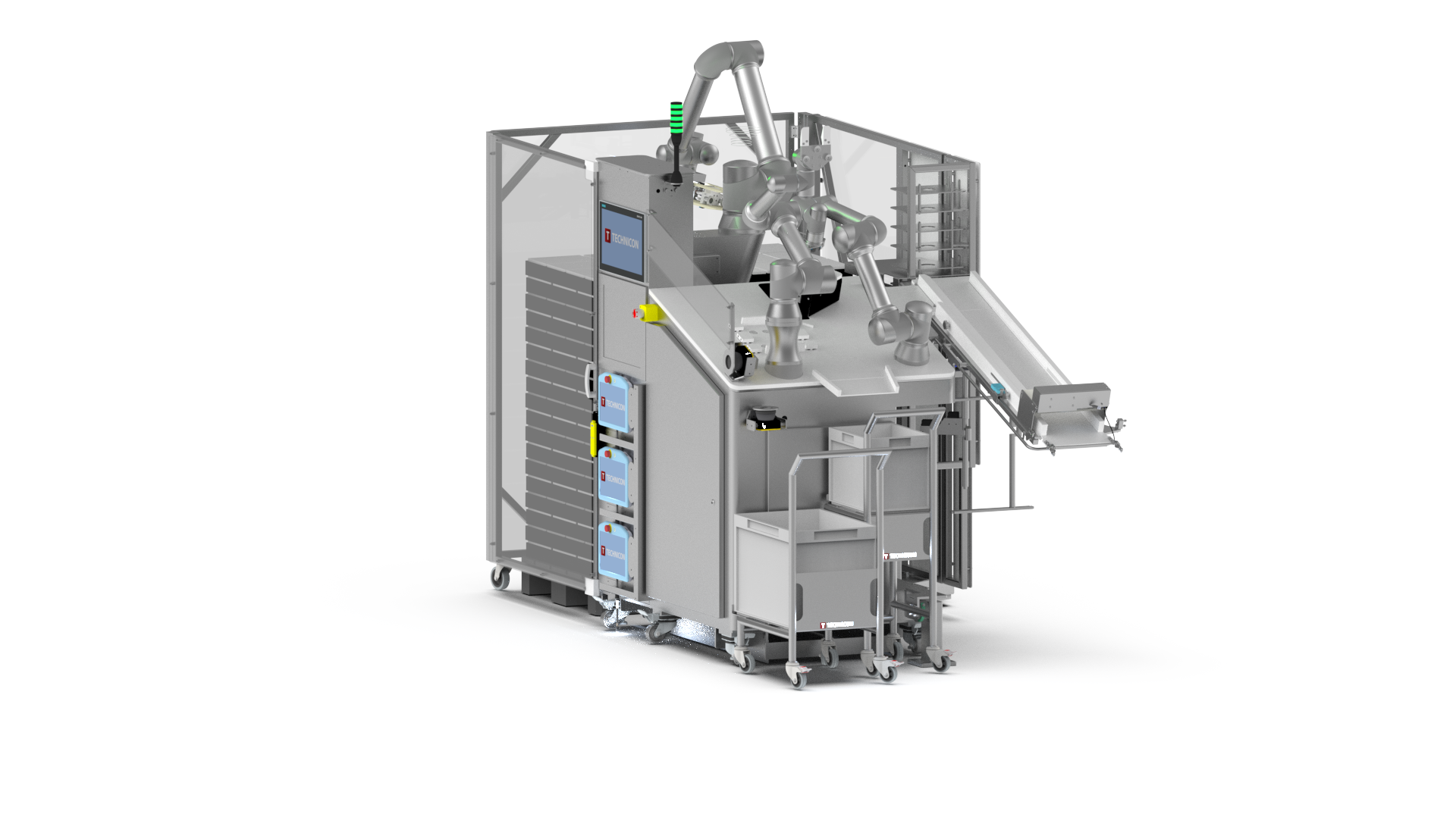

Automatic Cartridge Infeed

Innovative, modular, plug & play robot solution reduces manual infeed of empty cartridges. Automatic Cartridge Infeed frees resources and ensures systematic, efficient depalletizing, infeed and inspection of cartridges.

Continuous manual filling of empty cartridges into washing/filling machines is repetitive and monotonous work. Manual inspection of cartridges also risks overlooking chips and cracks. Human error increases the risk of production stops and downtime.